MANUFACTURING PROCESSES

The sequence and interaction of monitoring and reporting processes is the NUOVA RID FLAGSHIP

These 3 simple flowchart showing the importance of related processes to avoid future complaints or misunderstandings.

An inspection test plan (i.t.p) with alla processes shown included RULES-EQUIPMENT could be supplied on client request.

SERVICE STATEMENT:

- WELDING PROCESS

ON STARTING RAW MATERIAL BY OUTSOURCING QUALIFIED SUPPLIERS WITH WPS/PQR APPROVED BY INSPECTING AUTHORITY, AVAILABLE ON REQUEST FOR CUSTOMERS. - SKILLED TO PRODUCE

BW FITTINGS (HOT/COLD FORMING) ACC.TO ASME RULES –ANSI RULES-MSS RULES – EN /DIN RULES AND ALL B.W FITTINGS INTERNATIONAL STANDARD RULES ,CLIENT DRW AND SPECIAL MATERIAL MDS. - MATERIALS

STAINLESS STEEL:(AUSTENITIC,FERRITIC,DUPLEX.SUPERDUPLEX ,UNS31254,UNS N08904

NICKEL BASE ALLOYS(Ni200/201,MONEL400,INCONEL –INCOLOY-HASTELLOY VARIOUS GRADES.

COPPER AND COPPER Ni ALLOYS(90/10)

TITANIUM AND TITANIUM ALLOYS

FOR EVERY MATERIAL UNKNOWN AN EVALUATION WITH MATERIAL RULE AND EVENTUAL TEST COULD BE DONE. - HEAT TREATMENT

NUOVA RID HAS A LONG EXPERIENCE IN H.T. FOR ALL MATERIALS ,NO CLAIM

IT’S POSSIBLE TO DO HEAT TRATMENT UP TO 60” FOR STUB ENDS AND ALL RANGE OF PRODUCTION FOR CAPS,REDUCERS,REINFORCED PIPE BRANCHES AND ALL TYPE OF FITTINGS ACC.TO CLIENT DRAW.

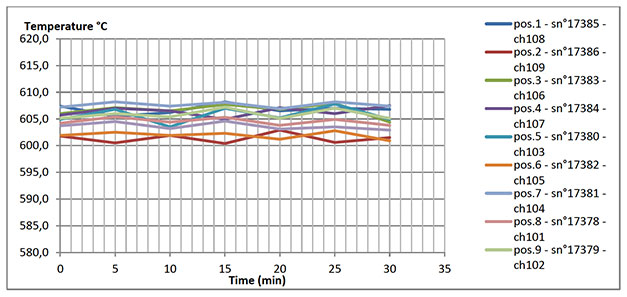

HEREWITH ATTACHED YOU CAN FIND THE HEAT TREATMENT UNIFORMITY SURVEY T° DIAGRAM ACC.TO ASME A991 LAST EDITION FOR NORSOK STANDARD M-650 ED.4 +MDS T01 REV.5. TITANIUM

GR.2